How reorganising an assembly line boosts productivity by up to 30 percent.

Improving the productivity of manual assembly work is a key factor for remaining globally competitive. Anyone who fails to harness the many benefits of lean production approaches such as the one-piece-flow concept will quickly fall behind. A medical technology customer who was well aware of this fact asked item pluspartner Plan B to build it a new assembly line. Founded in 1998, Plan B has become a globally oriented all-rounder in specialist mechanical engineering.

Both lean and ergonomic

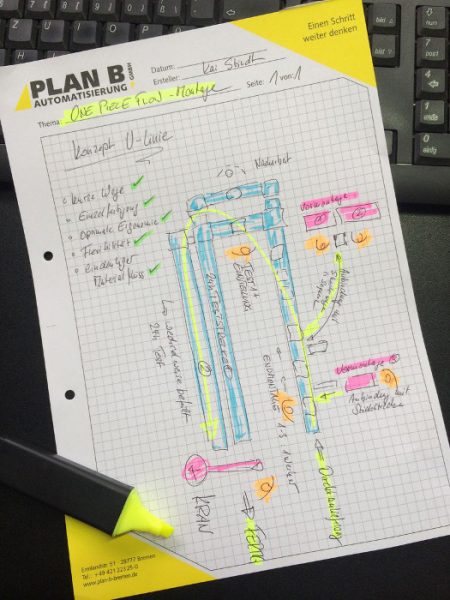

The customer required an assembly line that enables it to optimise workflows and cut both throughput and manufacturing times. The new system needed to be sufficiently flexible to manufacture several products on a single line. An ergonomic workplace design was also considered important. Faced with a wide choice of production systems, the customer had difficulty finding the ideal solution. After examining the complete requirements profile, Plan B suggested using a U-shaped assembly line and converting production to the one-piece-flow principle. Would you like to know more about one-piece-flow? You can deepen your knowledge in a special online training at the item Academy.

Production based on one-piece-flow principle

The one-piece-flow principle – also called an “employee-centred workflow” – was implemented for the first time in the Toyota production system. The ground-breaking idea was for one employee to work on each production part in a given assembly process until it is finished. On the customer’s new assembly line, the various products are now also made at fixed workstations according to defined schedules.

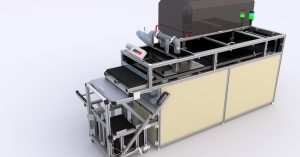

One employee starts at the first station of a cell and accompanies a production part in a continuous production process from station to station. As soon as the product is finished at the final station, he repeats the process from the start. A U-shaped arrangement of the individual assembly stations – the U-line – is an ideal solution for locating the start and end points of a cell as close together as possible and simplifying communication between staff. Good previous experience with the flexibility and strength of our solutions led Bremen-based company Plan B to use our Profile Tube System D30.

Entire assembly line benefits from lean production

One key benefit of the assembly line designed according to one-piece-flow criteria lies in the fact that stocks of semifinished products are reduced, as are throughput and manufacturing times. A further positive aspect of the one-piece-flow principle is that employees learn to perform all processes at the various workstations. This makes assembly processes more varied and the customer’s staff are more motivated.

Overall, the many advantages of an assembly line of this kind easily achieve a productivity increase of up to 30 percent. Plan B’s customer also found that the proportion of value added per employee rose significantly. What’s more, less reworking was required and there were fewer quality problems. Another of the system’s plus points is its flexibility. The individual modules in the U-line can be extended or modified on an ongoing basis, which means the item pluspartner’s customer is now using an assembly line that is also equipped for future challenges.

Are you interested in fascinating reports and innovations from the world of lean production? Then, we have the perfect solution for you – simply subscribe to the item blog by completing the box at the top right!